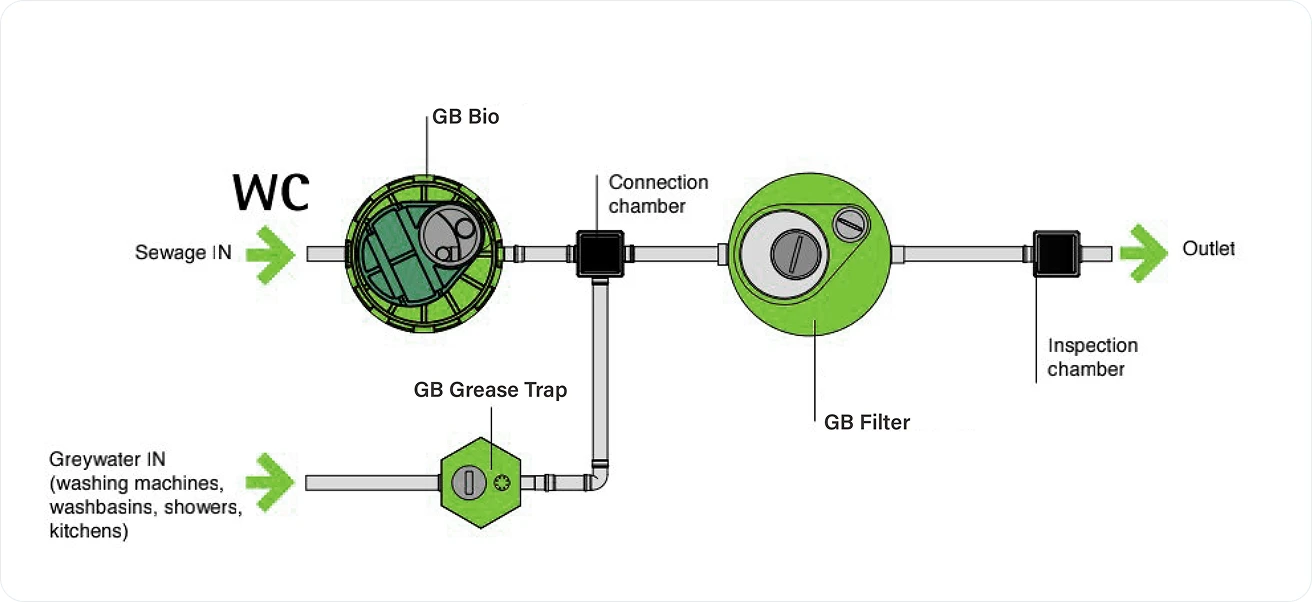

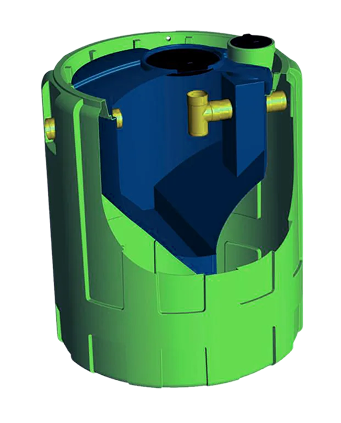

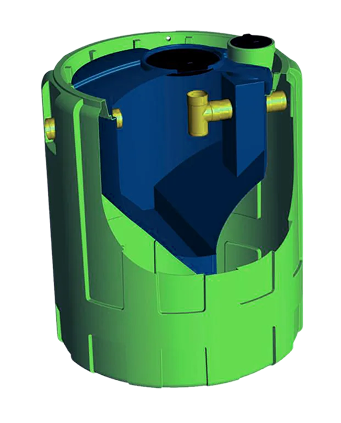

BIO TANK

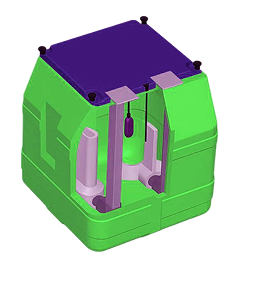

The GB Bio is an advanced tank system that improves primary

wastewater treatment by incorporating both settling and

digestion processes within a ribbed, high-strength

polyethylene shell. It includes a settling chamber located at

the top, which captures suspended solids, and a digestion

chamber below, where settled sludge undergoes anaerobic

break-down.

GB GREASE TRAPS

GB Grease Traps are essential for the pre-treatment of

greywater generated from kitchens, washbasins, showers, and

laundry facilities. These units function by removing

substances lighter than water, such as fats, oils, and grease,

which are prevalent in domestic and commercial kitchens. The

separation is purely physical, enabling the trap to collect

floating materials before they reach main treatment systems.

Grease removal is necessary to prevent interference with

biological and mechanical processes in subsequent treatment

phases. Additionally, sand and dense particles are settled out

as part of this process, protecting equipment and enhancing

overall efficiency.

GB FILTER

The filter system is an all-in-one solution that combines

grease removal, solid settling, anaerobic digestion, and

biological filtration in a compact format. It is designed for

small communities, institutions, or commercial facilities and

includes three components: a GB Grease Trap, a GB Bio Tank,

and a GB Filter. Together, these units provide a complete

primary and secondary treatment train.

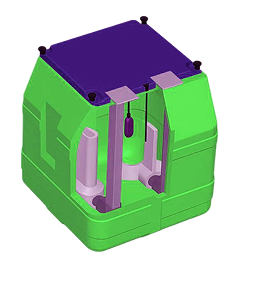

GB LIFTING STATIONS

The GB Lifting Stations are complete wastewater pump systems

designed for residential and commercial use. They are

constructed from heavy-duty polyethylene and come with a

central access cover for servicing pumps and accessories. The

internal pumps are available as single or dual units and are

built from synthetic, cast iron, or stainless steel

mate-rials. The system includes essential components such as a

ball valve, non-return valve, level regulators, and optional

electrical control panels for larger models.

GB OIL SEPARATOR

The GB Oil Separator is a robust, molded polyethylene unit

designed to separate oils, hy-drocarbons, and other floatable

pollutants from wastewater. Available for peak flows from 0.5

to 30 liters per second, it features both central and lateral

screw-on inspection covers, PVC inlet and outlet fittings with

neoprene seals, and optional elbow or T-connec-tor

configurations for easy adaptation. Screw-on covers